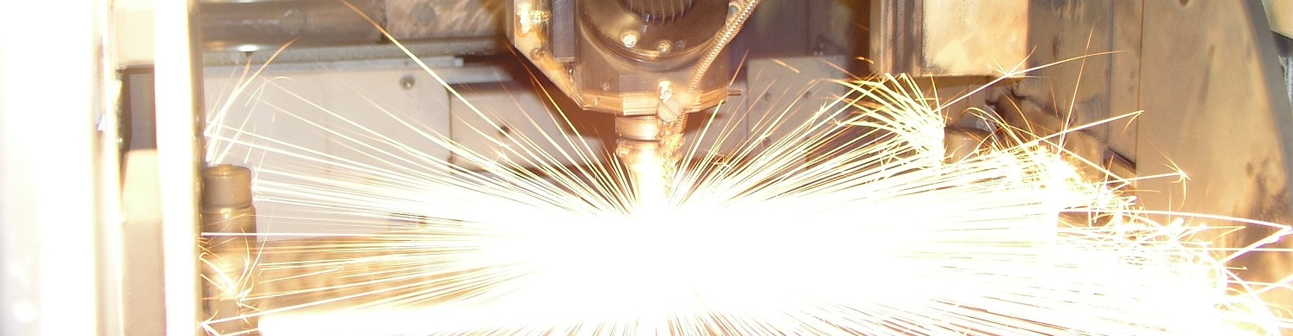

One of our specialties at Production Cutting Services is the efficient manufacturing of close tolerance machined parts. We have both horizontal and vertical CNC machining capabilities to manufacture components out of virtually any type of material.

Our Horizontal Machining Centers are equipped with palletized load-unload systems. Work holding fixtures mounted on tombstones give us the ability to machine in 4 axis efficiently for precise component part processing. Work envelope dimensions up to 41.34″ diameter x 51.8″ high allow us to machine a wide range of part configurations continuously on a 24/7 basis.

At PCS, Inc. our Vertical Machining Centers are capable of machining parts in up to 4 axes of motion enabling us to achieve outstanding accuracy and consistent repeatability.

We have a strong background working with many types of metal as well as a variety of plastics. Our technically-oriented machinists are capable of executing a diverse range of standard and specialty machining processes for the production of both simple forms and geometrically complex features. We are ISO 9001:2008 certified with a comprehensive quality management system to monitor all of our manufacturing, testing, and inspection processes. Our Process Development Group is also available to partner with your design engineers to reduce costs for parts and downstream assembly activities. We provide comprehensive evaluation of all new projects to ensure that we select the most efficient and cost-effective method for production. Whether you need high volume production parts or “one off” prototype parts, our capabilities guarantee that we will meet or exceed your expectations. Contact us at any time to learn more.

GALLERY

CNC Machining Highlights

Machine Type – Horizontal Machining Center

Mazak HCN6800 w/8 Pallet Pool

CNC Control Capabilities

Work envelope 41.34″ diameter x 51.8″ high. Up to 5 axis machining

Machine Type – Vertical Machining Center

Various Haas VMC’s (VF2 – 4xis, VF3, VF6, VF7, VF10)

CNC Control Capabilities

Work envelope up to 25″x 32″ x 120″

Machining Processes Available

- Milling

Drilling

Boring

Threading

Tapping

Thread Milling

Internal Forming - Counterboring

Countersinking

Pocketing

Profiling

Reaming

Broaching

- Milling

Materials – Tubing, I Beam, Channel, Bar Stock, Plate

- Aluminum

Brass

Carbon Steel - Alloyed Steel

Stainless Steel

Some Plastics

- Aluminum

IS Files Used

- AutoCAD (.dwg .dwz)

SolidWorks (sldprt, slddrw, slddrt)

Gibbs

DXF - IGS

CAMDXF

PDF

IGES

- AutoCAD (.dwg .dwz)

Industry Focus

- Agriculture Equipment

Construction Equipment

Office Furniture

On-Road / Off-Road

Open Air and Covered Support Structures - Non-Residential Construction

Railroad

OEM

Energy

Military

- Agriculture Equipment

Industry Standards

ISO 9001:2008

ASTM/ANSI

Manufacturing Model

- Lean Applications

High Volume - Low Volume

Prototype / Service Part

- Lean Applications