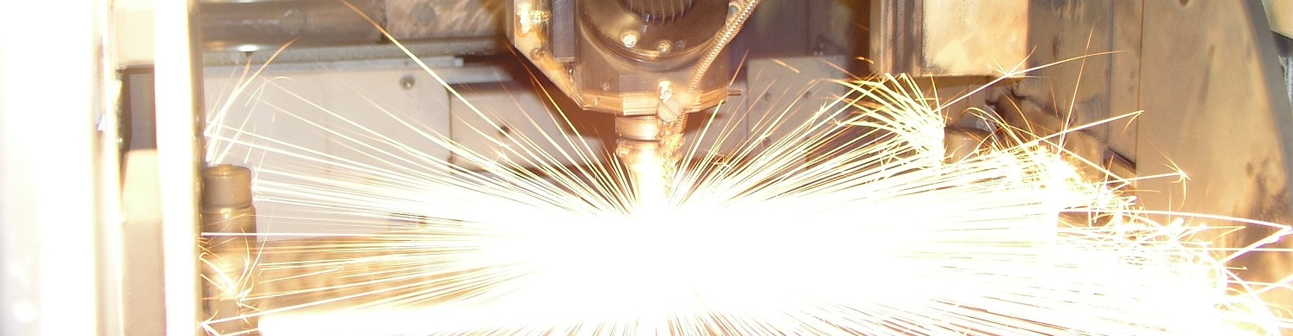

At Production Cutting Services, we offer numerous fabrication and machining options to maximize quality while minimizing production costs. The part is machined from a piece of rectangular tube stock to locational tolerances of ±0.020”. This part could have been made using any one of our available processes, such as a 3D laser, vertical machining center, or a horizontal machining center, which is equipped with an 8-pallet scheduling system. After collaborating with the customer’s engineering team, our Process Development group was able to select the most effective method while reducing part cost by 14% over the original design, at an efficient supply of 14,000 pieces annually. By having multiple options at our disposal, customers can be assured their parts are being produced using the optimal technique for their specific material choice, part geometry, and production volume. For more details, please contact us directly.